Acceptance of the stage before the mechanical engineering equipment self-inspection points

Stage mechanical engineering The final procedure is acceptance, which is the most important process. Before entering the acceptance process, the contractor must do a series of preparatory work, so that the acceptance work smoothly. The main basis for all acceptance work is the stage machinery system contract (including bidding documents, deepening the design and design with the document), design drawings, national standards and industry standards. Site project manager must be on the industry standard WH / T 27-2007 "stage mechanical acceptance testing program" is very understanding and familiar with, in order to correctly grasp their work in the acceptance process.

认1 device self-test report

Equipment self-test is responsible for the project manager, in the equipment before the acceptance of an important work, found in the self-test problems should be resolved before acceptance. After the installation and commissioning of the equipment, the equipment should be tested according to the contents of the contract and the technical conditions stipulated in the contract. The equipment self-test report shall be provided. In any case, the equipment self-test should be carried out one by one, not missing. Self-test equipment, including the provisions of the contract, control the operation of all functions of the device self-test.

1.1 Equipment appearance inspection

The project manager should pay great attention to the external quality of the engineering equipment, the appearance of the equipment to the acceptance of the first impression of the acceptance work is essential. Note the focus is:

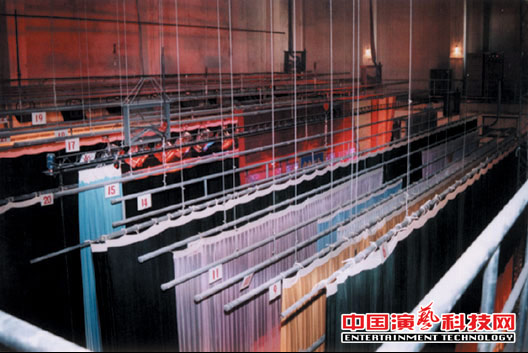

(3) the equipment has been correctly and firmly installed; (4) steel structure without affecting the strength, stiffness and performance of the obvious deformation (1) equipment and the surrounding environment clean; (2) equipment layout and design drawings exactly the same, complete; (6) the electrical and control equipment cabinet layout neat, wiring specifications beautiful, complete information within the information bag; (7) surface coating uniform, no leakage coating, the use of electrical equipment, Cracks and shedding. 1.2 Inspection of equipment characteristics and safety markings (1) The nameplate indicating the characteristics of a single device shall be complete; (2) The safety markings used in the stage equipment, if the boom is allowed to carry under different loads (uniform load or concentrated load) (Usually provided in the main stage side wall is easy to observe the place), a variety of safety warning signs and other checks; (3) security warning signs (light, sound, signs, etc.) inspection. 1.3 Equipment performance testing equipment performance testing includes equipment safety performance and safety equipment inspection, equipment technical parameters (such as load, speed, stroke, stop and accuracy, movement mode, synchronization and accuracy, chain, special equipment, special requirements, etc.) Control system performance check. Through the specific technical parameters of the test, to confirm the equipment (including control) capacity, movement and accuracy, and then

Equipment performance。 1.3.1 Safety performance inspection and safety facilities Check the safety function of the stage machinery and equipment and its control system is the basic guarantee for the long-term, stable and safe operation of the stage machinery. The test of the safety facilities is the prerequisite for the confirmation of the mechanical safety function of the stage. All safety facilities of the equipment are tested item by piece. Safety check First of all, the safety of a single device to check and test to ensure safe and reliable action. The items to be inspected are safety switches and safety circuits, including: working stroke switches and overstroke switches; anti-shear switches; loose rope switches for hoisting systems; stacking switches (if any) for winch systems; (Protection doors, safety rails, protective net, etc.) and its associated switch with the host; the safety protection device (protective doors, safety rails, protective net, etc.) and its associated switch; Intermittent protection circuit; signal. For the equipment group to add the following checks: synchronous motion error control loop; speed error control loop; equipment group interlock switch; emergency stop control components; control electrical safety circuit; security warning signal. Inspection and testing shall be carried out at different loads and different speeds, and the safety switch shall be triggered and the action of the switch shall be confirmed. The test of the anti-shear switch on the lift should cover the movement and rest, the opposite movement, the same way to chase the movement, etc., the test speed should be relative speed. 1.3.2 Technical parameters Test technical parameters include a single device motion parameters and accuracy detection (load, speed, stop accuracy, etc.), as well as equipment group operation and precision detection. Equipment group operation and precision detection should be carried out according to different group mode (free type group, locking type group, synchronous type group, chain type group): synchronization requirements of the equipment to be synchronized precision test and synchronous motion error control test; Speed requirements of the equipment to speed accuracy testing and speed motion error control test; chain type of equipment to carry out the chain test. Technical parameters of the test should also be in different load conditions and different speed conditions. Test items are load test, speed test, stop accuracy test, synchronization accuracy test, equipment chain motion test. (1) Load test ① The load test load of the lifting equipment such as the suspension equipment and the lifting platform is 1.25 times of the rated load, and the full stroke load test is carried out at the rated speed to confirm the lifting capacity of the equipment under the test load condition and the following (For the purpose of confirming the load retention of the brake, the brake torque of the brake is to be individually commissioned); the clutch and the separation of the clutch and the load holding device ; Hydraulic, pneumatic and electrical system components. Driving devices using traction pulleys shall be tested at full travel for 1.3 times the safe working load and the balance at the rated load. ② load and rotation equipment (especially the platform and turntable) load test movement and rotation equipment load test, is the driving device and the ability to verify the brake, carrying steel structure does not need to load test to design calculations. ③ overload protection switch test to 1.2 times the rated load, rated speed overload protection switch test, in any case, the device can not run. (2) speed test speed test, including rated speed, speed control equipment speed and low speed stability test. ① Determine the speed of movement of the equipment, compared with the rated speed, to determine whether the error within the design allowable range. When the design is not specified, the allowable error should be less than 8% of the rated speed. ② according to the design of the speed control performance test speed. ③ to speed control equipment, low-speed operation performance test to confirm the equipment at the lowest speed running smoothly. The speed value can be read directly on the instrument of the control station while confirming that the display of the control station coincides with the actual value. (3) stop accuracy test in the rated load and rated speed conditions, set a different trip for a single device stop accuracy test. The stop accuracy value should be measured in the field and compared with the displayed value on the control station. Data can only be read directly on the control station after confirming the consistency of the two. (4) synchronization accuracy test set different travel synchronization accuracy test to the maximum absolute difference of equipment movement as a synchronization accuracy error, the error should be within the design value range. (5) equipment chain motion test on the chain-type group movement of the equipment, to carry out the conditions of the equipment under the linkage testest. In the equipment under normal conditions, the equipment group can move according to the instructions; in the artificial simulation of the accident state, damage the chain conditions, the equipment group to stop moving.t

1.3.1 Safety performance inspection and safety facilities Check the safety function of the stage machinery and equipment and its control system is the basic guarantee for the long-term, stable and safe operation of the stage machinery. The test of the safety facilities is the prerequisite for the confirmation of the mechanical safety function of the stage. All safety facilities of the equipment are tested item by piece. Safety check First of all, the safety of a single device to check and test to ensure safe and reliable action. The items to be inspected are safety switches and safety circuits, including: working stroke switches and overstroke switches; anti-shear switches; loose rope switches for hoisting systems; stacking switches (if any) for winch systems; (Protection doors, safety rails, protective net, etc.) and its associated switch with the host; the safety protection device (protective doors, safety rails, protective net, etc.) and its associated switch; Intermittent protection circuit; signal. For the equipment group to add the following checks: synchronous motion error control loop; speed error control loop; equipment group interlock switch; emergency stop control components; control electrical safety circuit; security warning signal. Inspection and testing shall be carried out at different loads and different speeds, and the safety switch shall be triggered and the action of the switch shall be confirmed. The test of the anti-shear switch on the lift should cover the movement and rest, the opposite movement, the same way to chase the movement, etc., the test speed should be relative speed. 1.3.2 Technical parameters Test technical parameters include a single device motion parameters and accuracy detection (load, speed, stop accuracy, etc.), as well as equipment group operation and precision detection. Equipment group operation and precision detection should be carried out according to different group mode (free type group, locking type group, synchronous type group, chain type group): synchronization requirements of the equipment to be synchronized precision test and synchronous motion error control test; Speed requirements of the equipment to speed accuracy testing and speed motion error control test; chain type of equipment to carry out the chain test. Technical parameters of the test should also be in different load conditions and different speed conditions. Test items are load test, speed test, stop accuracy test, synchronization accuracy test, equipment chain motion test. (1) Load test ① The load test load of the lifting equipment such as the suspension equipment and the lifting platform is 1.25 times of the rated load, and the full stroke load test is carried out at the rated speed to confirm the lifting capacity of the equipment under the test load condition and the following (For the purpose of confirming the load retention of the brake, the brake torque of the brake is to be individually commissioned); the clutch and the separation of the clutch and the load holding device ; Hydraulic, pneumatic and electrical system components. Driving devices using traction pulleys shall be tested at full travel for 1.3 times the safe working load and the balance at the rated load. ② load and rotation equipment (especially the platform and turntable) load test movement and rotation equipment load test, is the driving device and the ability to verify the brake, carrying steel structure does not need to load test to design calculations. ③ overload protection switch test to 1.2 times the rated load, rated speed overload protection switch test, in any case, the device can not run. (2) speed test speed test, including rated speed, speed control equipment speed and low speed stability test. ① Determine the speed of movement of the equipment, compared with the rated speed, to determine whether the error within the design allowable range. When the design is not specified, the allowable error should be less than 8% of the rated speed. ② according to the design of the speed control performance test speed. ③ to speed control equipment, low-speed operation performance test to confirm the equipment at the lowest speed running smoothly. The speed value can be read directly on the instrument of the control station while confirming that the display of the control station coincides with the actual value. (3) stop accuracy test in the rated load and rated speed conditions, set a different trip for a single device stop accuracy test. The stop accuracy value should be measured in the field and compared with the displayed value on the control station. Data can only be read directly on the control station after confirming the consistency of the two. (4) synchronization accuracy test set different travel synchronization accuracy test to the maximum absolute difference of equipment movement as a synchronization accuracy error, the error should be within the design value range. (5) equipment chain motion test on the chain-type group movement of the equipment, to carry out the conditions of the equipment under the linkage testest. In the equipment under normal conditions, the equipment group can move according to the instructions; in the artificial simulation of the accident state, damage the chain conditions, the equipment group to stop moving.t 1.4 Control and operating system functions Check the control and operating system function check the main items include: (1) operating mode: automatic, manual and set, programming, scene sequence and other mode one by one to confirm; (2) operating system priority: (3) operating equipment: different operating equipment such as the main console, mobile console, portable operation panel and other forms of operation of the operator to confirm the operation of different devices (including the exclusive test); (4) operational safety management (6) equipment grouping operation; (7) the scene of the physical parameters of the system, the operation of the system, the operation of the system, (8) the chooseion and neglect of the equipment in the free-form grouping (ie, the temporary chooseion of a device or the neglect of a device in the existing equipment group); (9) the various operating modes of the equipment (single equipment movement, Equipment group movement, etc.) (ie, to change the device operating parameters before a single device movement; (10) Emergency stop function and its display function confirmation; (11) Uninterruptible power supply (UPS), continuous power supply (UPS), emergency power supply (UPS), emergency power supply (UPS) (12) warning system (light, sound, etc.) to confirm the state; (13) print and file management system to confirm, in particular, failure alarm history, etc. to confirm; (14) operation control system testing, Prechooseion equipment, parameter setting, marshalling operation, status display, emergency stop, safety circuit, automatic and manual, warning and other functions in the equipment performance testing has been carried out. 1.5 Manual release function test of the fire curtain The test should be carried out to confirm the manual release function of the fire curtain to confirm that the total closing time, deceleration buffer off time, positioning deceleration and cushioning performance in non-power condition meet the relevant standards. 1.6 Noise Testing The noise test of a single device is usually performed in the Auditorium according to the agreed conditions and methods. If there is no agreement, the usual conditions are: the curtain open, according to the stage layout hanging one-third of the curtain, side stage and rear stage of the curtain closed in the audience row of the first row of 1.5 m height, so that the equipment under test Run at rated speed. Test method for GB / T 17248.1-2000 "Acoustic machines and equipment emitted by the noise measurement of the working position and other designated position of the sound pressure level of the basic standards for the use of guidelines" and GB / T 17248.2 ~ GB / T 17248.5 series of standards Related methods. When there are special requirements, the equipment of the machine next to the noise test.

1.4 Control and operating system functions Check the control and operating system function check the main items include: (1) operating mode: automatic, manual and set, programming, scene sequence and other mode one by one to confirm; (2) operating system priority: (3) operating equipment: different operating equipment such as the main console, mobile console, portable operation panel and other forms of operation of the operator to confirm the operation of different devices (including the exclusive test); (4) operational safety management (6) equipment grouping operation; (7) the scene of the physical parameters of the system, the operation of the system, the operation of the system, (8) the chooseion and neglect of the equipment in the free-form grouping (ie, the temporary chooseion of a device or the neglect of a device in the existing equipment group); (9) the various operating modes of the equipment (single equipment movement, Equipment group movement, etc.) (ie, to change the device operating parameters before a single device movement; (10) Emergency stop function and its display function confirmation; (11) Uninterruptible power supply (UPS), continuous power supply (UPS), emergency power supply (UPS), emergency power supply (UPS) (12) warning system (light, sound, etc.) to confirm the state; (13) print and file management system to confirm, in particular, failure alarm history, etc. to confirm; (14) operation control system testing, Prechooseion equipment, parameter setting, marshalling operation, status display, emergency stop, safety circuit, automatic and manual, warning and other functions in the equipment performance testing has been carried out. 1.5 Manual release function test of the fire curtain The test should be carried out to confirm the manual release function of the fire curtain to confirm that the total closing time, deceleration buffer off time, positioning deceleration and cushioning performance in non-power condition meet the relevant standards. 1.6 Noise Testing The noise test of a single device is usually performed in the Auditorium according to the agreed conditions and methods. If there is no agreement, the usual conditions are: the curtain open, according to the stage layout hanging one-third of the curtain, side stage and rear stage of the curtain closed in the audience row of the first row of 1.5 m height, so that the equipment under test Run at rated speed. Test method for GB / T 17248.1-2000 "Acoustic machines and equipment emitted by the noise measurement of the working position and other designated position of the sound pressure level of the basic standards for the use of guidelines" and GB / T 17248.2 ~ GB / T 17248.5 series of standards Related methods. When there are special requirements, the equipment of the machine next to the noise test.